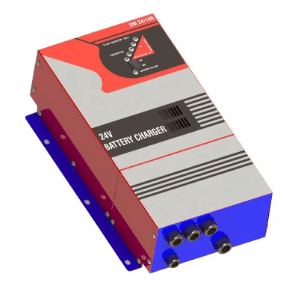

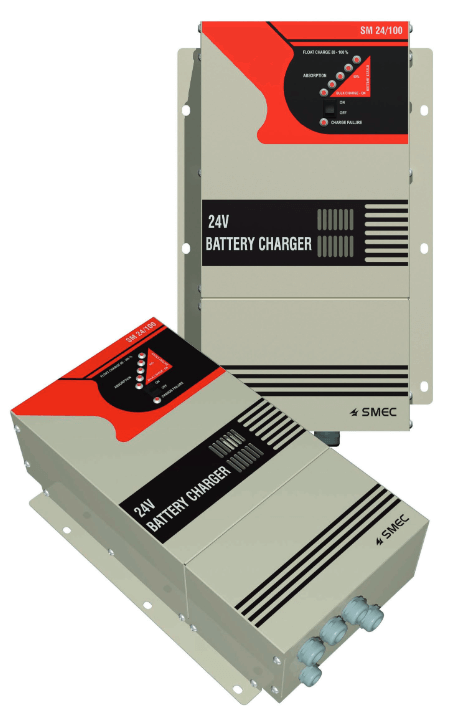

Battery Charger

SUITABLE FOR ALL EMERGENCY

POWER REQUIREMENTS IN HARSH

ENVIRONMENT

A general-purpose fully automatic battery charger / rectifier, converting

AC to DC ranging from 110 V – 415 V AC to 12 V / 24 V / 48 V DC (considering

the purpose & client requirements as per standards). Can be used for

different battery types. Protection against short circuits, overload and

high temperature.

Why SMEC?

Features:

- Nominal output Voltage – 12 / 24 / 48 V DC

- Total charge Current – 10 / 20 / 40 / 100 A

- Number of battery outlets – 1 No.

- Battery capacity Range – 200 – 1000 Ah

- Nominal input Voltage – 110 / 230 / 415 V AC 50/60 Hz Input Voltage range – +10% / -10%

- Power Supply Mode – Yes

- Display / Read-out – LED Display

- Galvanic Isolation – Yes Weight – 6 – 15 Kg

- Charge Characteristic – 3 Stage

- Charger Charge Current Bulk – 0-100 A (As per ratings)

- Charge Voltage Absorption – 28.5 V

- Absorption Time – 1 – 2 Hours

- Charge Voltage Float – 26.5 V

- Temperature Sensor – Optional

- DC Voltage Compensation – Optional

- Full Load consumption – As per ratings

- Current Control Function – Yes

- Temperature Range – 0-55 Degree Celsius

- Cooling – Forced Air Cooling

- Protection Degree – IP 23

- Protections – Over Voltage/ Over Current/ Over

- Load / Over Temperature/ Short Circuit