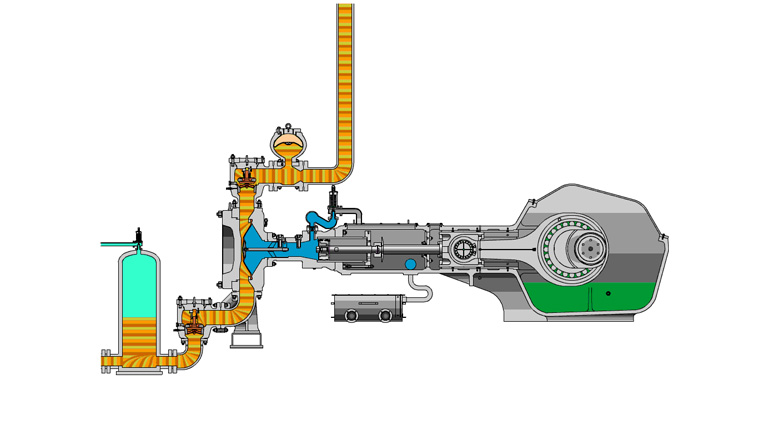

Mud Pump System

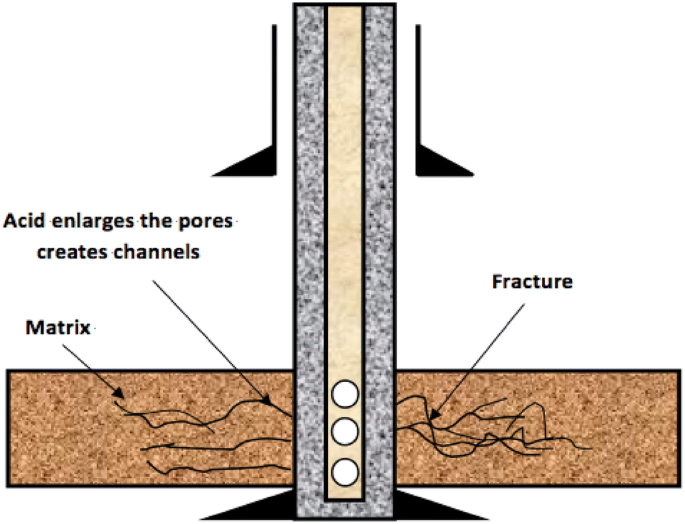

Mud pump system is the equipment responsible for the circulation of the drilling fluid during drilling operation. The system comprises a reciprocating pump which circulates the drilling fluid, which is also known as “mud,” through the drill bit and back up to the surface. The pressure from the mud pump also prevents the drill bit from clogging. The drilling fluid is drawn out of the pit by the pump’s suction, and it is then pushed back up the well by the pump’s piston. This procedure helps to remove any cuttings or debris that may have been generated during the drilling process in addition to circulating the fluid.

The mud pump system comes in a wide variety of working mechanisms – the piston pump being the commonly applied form which uses a piston to draw and push the mud through the hose. Plunger type systems work similar to piston pumps but are quieter and easier to operate. Application of hydraulic pumps is when there is need for extensive power, these pumps can be challenging to operate and are costly. Peristaltic pumps are the costliest, but the most powerful variety – they are commonly applied in very large scale drilling and mining operations.