Bulk Weight Monitoring System

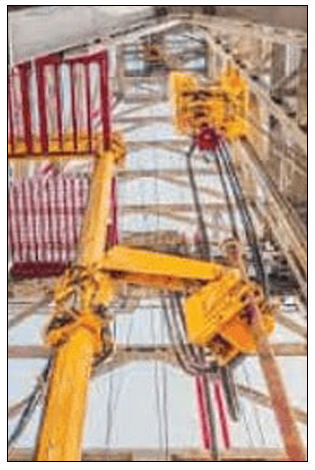

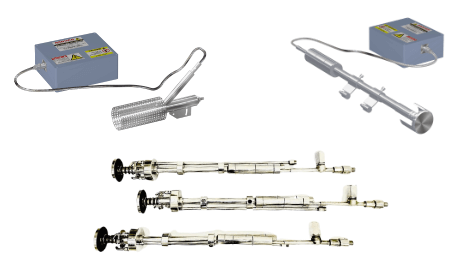

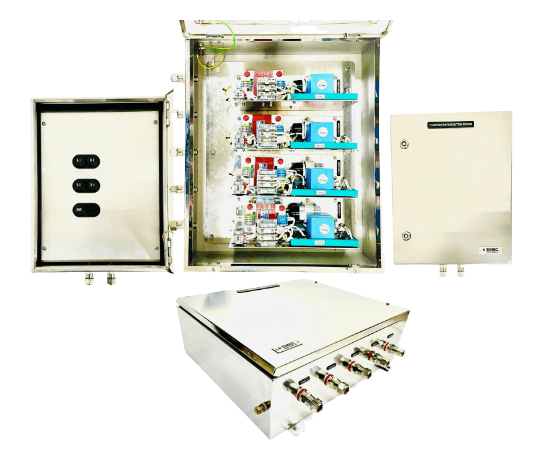

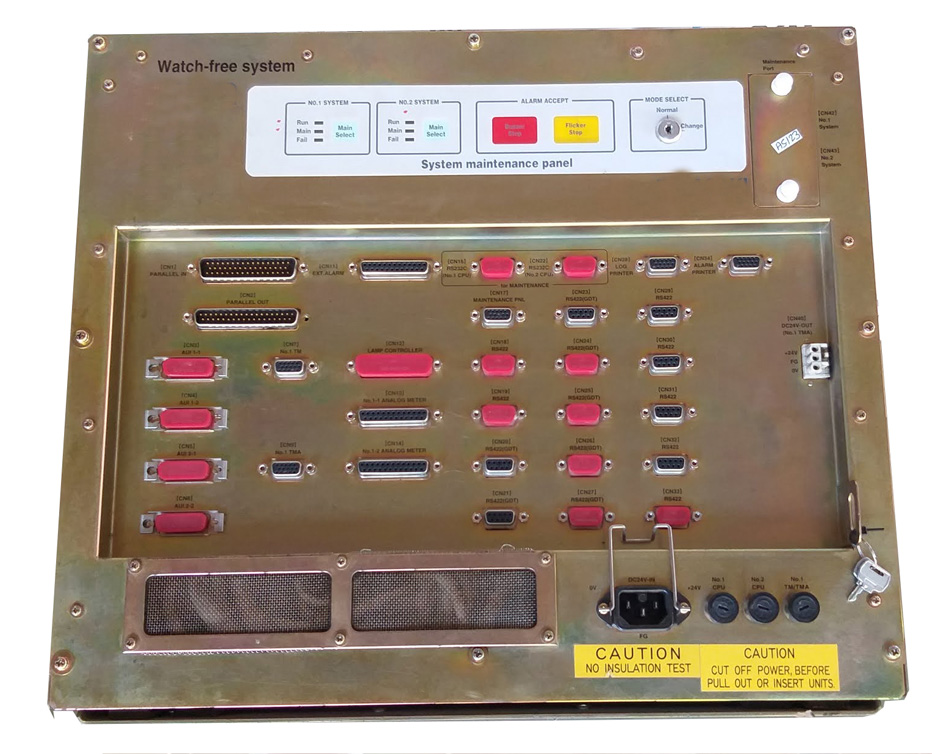

The bulk weight monitoring system is responsible for the measurement and data collection of the weight of the shipment. It continuously measures the weight as the shipment is being loaded to the facility. The weight is measured using load cells which provide a voltage to the processing device such as a PLC which then translates it to the corresponding numerical value of the weight of the shipment. It is essential for the industry as it aids in the planning and arrangement of different shipments according to its weight and volume that it occupies. The total weight of the shipments is crucial for the stability of the vessel/facility and accurate measuring devices are employed to obtain the shipments weight. Efficient utilization of cargo space is also necessary.

Flexicon bulk bag loss-of-weight batching systems consist of a Flexicon bulk bag discharger mounted on load cells which measure weight loss of each discharger during the batching cycle and transmit the information to a system controller.